Automation is the technology of the future that is here today! We specialize in integrating the latest technology to make the complex simple, the inefficient efficient, and the expensive practical. Our “out of the box” creativity has provided real world solutions when other automation integrators have declined or offered less effective designs. Let us provide you a concept to your manufacturing challenge. From automatic assembly of small components to assembly lines capable of handling large parts or assemblies, Capital can meet your automation needs. Contact Capital today!

TYPES OF SYSTEMS

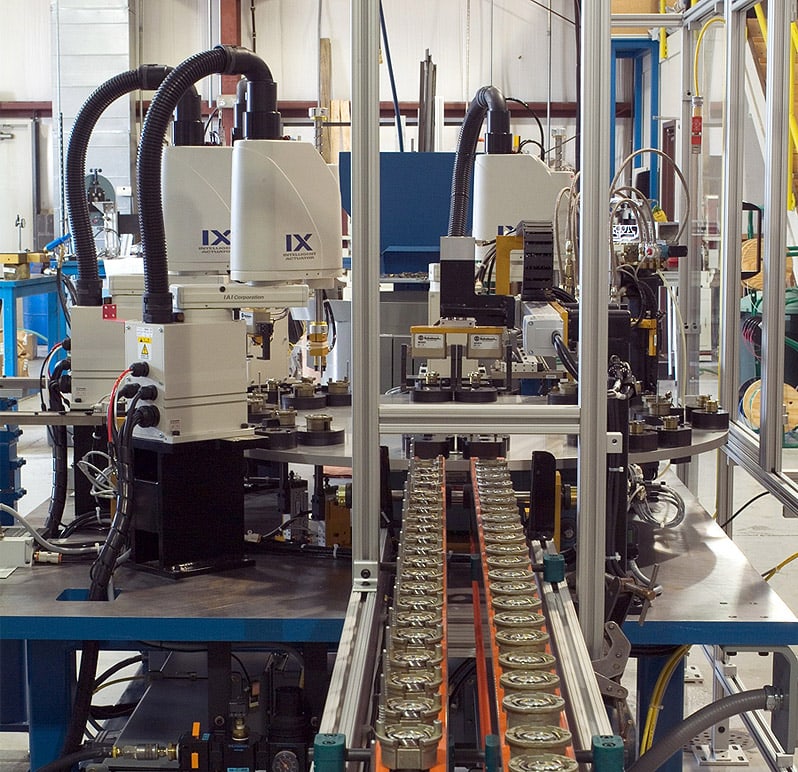

ROBOTIC

Capital Industries has broad experience in the design and implementation of robotic cells from one to multiple robots per assembly with production rates of multiple parts/second.

Robots are a very efficient method of manufacturing or processing multiple parts (or families of parts) in one automated cell. Robots are also capable of adaptive applications when they are fitted with external sensors to complete a complicated task where dedicated tooling would not be possible or feasible. And robots are tireless when it comes to running 24/7.

ROBOTIC EXPERIENCE

- Assembly – Single to Multiple Robot Applications

- Vision Directed – Handle Varying Shapes and Locations

- Material Handling – Pick-n-Place, Stacking

- Palletizing – Packaging, Inventory JIT

- Machine Tending – Automate Load & Unload

- Hazardous Environments

ROBOTIC MANUFACTURERS

- Fanuc

- Motoman

- ABB

- Panasonic

- Adept

- NACHI

- Epson

- Staubli

- Kuka

DIAL ASSEMBLY

Dial assembly machines provide a compact and efficient platform for many assembly applications. Typically, dials are an excellent choice for a fully automatic or single operator semi-automatic application. Dials can be as small as two stations or more than twenty-four stations. The size of the dial typically increases with the part size and / or an increase in the number of stations.

Capital Industries designs the majority of dial machines with proven mechanical cam indexers (like Camco™). Cam indexers provide for a smooth acceleration/deceleration which minimizes vibration and part movement during the index. When operator interface or part loading is required, the utilization of safety light curtains allows dial assembly machines to provide an ergonomic, safe, and efficient solution for your application. Whether you need a large or small assembly or process dial, Capital can design the perfect dial for your application.

POWER & FREE

Power and free conveyors provide a way to transport product to various positions or stations along the production/assembly path. With parts typically secure on a palletized fixture, parts can move freely, accumulate, or advance through several different types of powered conveyor systems. These systems work especially well as an integrated segment among multiple assembly stations, providing oriented parts with precision stops to enable production tasks to be performed accurately.

Provide Capital with your specific requirements as a standalone material handling need or as part of a larger assembly process and we can design the right transport system for your application.